Have you ever wondered how to calculate the precise amount of weight some materials can handle? Let's suppose you want to build a old fashioned furniture for that audio system of yours using some nice wood you have in home and need to know if the wood will hold the audio weight. This can be achieved using formulas regarding strength of materials, more precisely the bending property.

1. Bending tensile strength (i.e. Yield strength or rupture tensile): The first thing we need in order to continue with our calculations is to discover what is the bending tensile strength of the material we are using. This value represent the edge where the material will break if that amount of pressure is applied to it. These values can be obtained from the suppliers (commercial materials) or a search in the net also can help. These values are not always expressed in the same unity, being the most common units: psi (pound per square inch), Map (mega pascal), N/mm2 (Newton per square millimeter), kgf/cm2 (kilogram-force per square centimeter), etc. None of them are better than other, they are just a way of see the pressure the material can hold. We are going to work with kgf/cm2 as this is one of the most used. If you find the bending tensile strength in some other unity you can use this site to convert it to kgf/cm2.

2. Choosing the material: The material we are going to use for the tests is the very well known Plexiglas (PMMA), some more info about this material can be obtained here. The Plexiglas tensile strength is around 11000 psi, thus this is about 773.4 kgf/cm2.

3. Defining the shape: Having the first property we can now discover how to calculate the weight some material can handle for a given shape. There are formulas for most of the shapes we can find over the market, for the sake of simplicity we are going to do calculations using the rectangular shape (the most common one). The properties used by the formulas depend on the way the shape is being hold, more precisely which side are supported by a base (foundation pillars). Using the example from the picture below we can clarify this.

From the picture above we have the following variables:

b is the side of the rectangle hold by the foundation pillars.

h is the height of the rectangle.

L is the side of the rectangle from pillar to pillar

P is the force applied over the shape.

As we are working with kgf/cm2 all measurement must be made using centimeters, and P must be calculated using kilogram-force (kgf). Kgf is just the weight of the material in kilograms.

4. Formulas: There are a couple of formulas that we are going to use to calculate the material. Below I present some of the formulas related to the rectangular shape. Notice the shape is formed by the b and h sides, also known as section.

Tr is the bending tensile strength in kgf/cm2.

F is a security factor (see section below).

Tf is the acceptable bending tensile strength calculated based on the security factor.

Mf is the maximum flexure (bending) moment in kgf

P is the force applied to the rectangular shape in kgf.

L1 is the distance from pillar 1 to the point where P is applied (in centimeters).

L2 is the distance from pillar 2 to the point where P is applied (in centimeters).

L is the distance from pillar to pillar.

I is the inertia momentum (no external forces being applied to the material).

y is a imaginary line that divides the height of the shape in 2.

W is the resistance module of the material (in cube centimeters)

b is the side of the shape hold by the pillars (in centimeters).

h is the height of the shape (in centimeters).

5 - Security Factor: This is a number made by certain considerations about the elasticity and discharge of the material and also based on the way (effort) the weight is going to be applied over the shape. The effort for the security factor is divided into 4 groups:

Security Factor

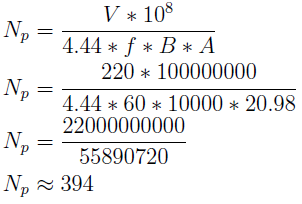

6 - Plugging the numbers: Now, suppose we have a piece of Plexiglas with these dimensions: b is 10 cm, L is 20 cm and h is 2 cm. What is the maximum weight in kilos this shape can hold? Remember we already know that the bending tensile strength (Tr) of the Plexiglas is about 773.4 kgf/cm2. Let's discover what is the appropriate flexure tensile (Tf) using the security factor. I'm going to use 8 for the security factor as the bending tensile strength from Plexiglas is very similar to wood and our audio system will sit statically over the shape.

P is going to be applied in the center of the shape (equilibrium point), in this way the weight is going to be distributed among the whole area. Now we are going to need a formula that relates the force applied with the shape we have. In order to do that we are going to need to calculate the resistance module of the material first.

Now we can relate Tf, Mf and W using the following formula:

So we discovered that our piece of Plexiglas can handle 129.204 kgf, or just simplifying, 129 kilograms. Now, it's just a matter of rearrange the formulas in order to solve for any variable you want.

7 - Other Shapes: Below I present some other shapes (section) formulas —if some of the variable is missing this means that the formula is the same as the rectangle shape. if you have trouble finding the one you want, just drop me a message and I can try to find some more information regarding it.

Have fun!

1. Bending tensile strength (i.e. Yield strength or rupture tensile): The first thing we need in order to continue with our calculations is to discover what is the bending tensile strength of the material we are using. This value represent the edge where the material will break if that amount of pressure is applied to it. These values can be obtained from the suppliers (commercial materials) or a search in the net also can help. These values are not always expressed in the same unity, being the most common units: psi (pound per square inch), Map (mega pascal), N/mm2 (Newton per square millimeter), kgf/cm2 (kilogram-force per square centimeter), etc. None of them are better than other, they are just a way of see the pressure the material can hold. We are going to work with kgf/cm2 as this is one of the most used. If you find the bending tensile strength in some other unity you can use this site to convert it to kgf/cm2.

2. Choosing the material: The material we are going to use for the tests is the very well known Plexiglas (PMMA), some more info about this material can be obtained here. The Plexiglas tensile strength is around 11000 psi, thus this is about 773.4 kgf/cm2.

3. Defining the shape: Having the first property we can now discover how to calculate the weight some material can handle for a given shape. There are formulas for most of the shapes we can find over the market, for the sake of simplicity we are going to do calculations using the rectangular shape (the most common one). The properties used by the formulas depend on the way the shape is being hold, more precisely which side are supported by a base (foundation pillars). Using the example from the picture below we can clarify this.

From the picture above we have the following variables:

b is the side of the rectangle hold by the foundation pillars.

h is the height of the rectangle.

L is the side of the rectangle from pillar to pillar

P is the force applied over the shape.

As we are working with kgf/cm2 all measurement must be made using centimeters, and P must be calculated using kilogram-force (kgf). Kgf is just the weight of the material in kilograms.

4. Formulas: There are a couple of formulas that we are going to use to calculate the material. Below I present some of the formulas related to the rectangular shape. Notice the shape is formed by the b and h sides, also known as section.

Tr is the bending tensile strength in kgf/cm2.

F is a security factor (see section below).

Tf is the acceptable bending tensile strength calculated based on the security factor.

Mf is the maximum flexure (bending) moment in kgf

P is the force applied to the rectangular shape in kgf.

L1 is the distance from pillar 1 to the point where P is applied (in centimeters).

L2 is the distance from pillar 2 to the point where P is applied (in centimeters).

L is the distance from pillar to pillar.

I is the inertia momentum (no external forces being applied to the material).

y is a imaginary line that divides the height of the shape in 2.

W is the resistance module of the material (in cube centimeters)

b is the side of the shape hold by the pillars (in centimeters).

h is the height of the shape (in centimeters).

5 - Security Factor: This is a number made by certain considerations about the elasticity and discharge of the material and also based on the way (effort) the weight is going to be applied over the shape. The effort for the security factor is divided into 4 groups:

- Static - The weight is applied over the material statically —this is kept in the same place all the time.

- Intermittent - The weight is applied and released from the material periodically.

- Alternate - The weight is applied periodically in both directions (up and down).

- Abrupt - The weight is released over the material abruptly and periodically.

For each group there is a security factor to be used for certain types of materials. If you don't know which type to use try to find the material that has the closest Tr of the material you are using.

| Static | Intermittent | Alternate | Abrupt | |||

| Cast iron | 6 | 10 | 15 | 20 | |||

| Soft Iron | 5 | 6 | 8 | 12 | |||

| Hard Iron | 4 | 6 | 8 | 12 | |||

| Wood | 8 | 10 | 15 | 20 |

P is going to be applied in the center of the shape (equilibrium point), in this way the weight is going to be distributed among the whole area. Now we are going to need a formula that relates the force applied with the shape we have. In order to do that we are going to need to calculate the resistance module of the material first.

Now we can relate Tf, Mf and W using the following formula:

So we discovered that our piece of Plexiglas can handle 129.204 kgf, or just simplifying, 129 kilograms. Now, it's just a matter of rearrange the formulas in order to solve for any variable you want.

7 - Other Shapes: Below I present some other shapes (section) formulas —if some of the variable is missing this means that the formula is the same as the rectangle shape. if you have trouble finding the one you want, just drop me a message and I can try to find some more information regarding it.

Solid circumference, where d is the diameter.

Tubular circumference, where d is the internal diameter and D is the external diameter.

Solid square, where a is the side.

Tubular square, where a is the external side and b is the internal side.

Have fun!